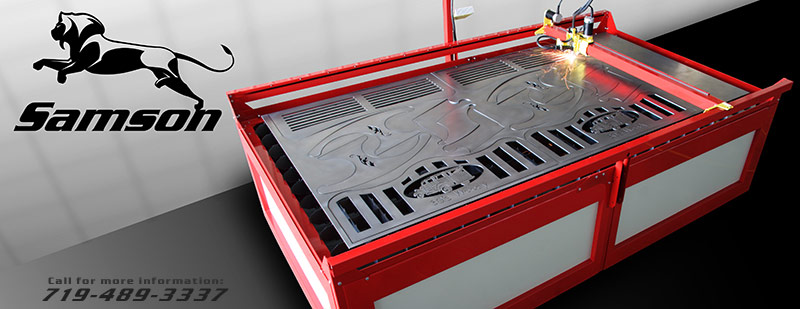

Plasma Cutting Table:

- 5ft by 10ft cutting area.

- Servo motors provide accurate, high-speed motion.

- Enhanced Digital Height Control² ™ for optimum performance. With this, the torch:

- Hovers a precise distance over the metal during cutting.

- Raises and lowers between cuts, sensing the material to set the exact pierce height before each cut.

- Detects and avoids collisions.

- Unique torch/tool holder:

- Clamps hand torch securely from the top for easy consumable changes.

- Easily accommodates machine torch with optional bracket. (Hand torch is preferred for best performance and economics.)

- Other tools can be quickly mounted in tool holder.

- Wide plasma torch compatibility (although some perform better than others).

- 3 year limited warranty and free technical support.

CAD/CAM Software

The DesignEdge™ Software designed specifically for plasma cutting is included with the machine. This complete CAD/CAM program not only creates designs, it also runs the machine (no other software

Specifications |

Power Required |

| 115/230 VAC, 50/60hz, 10A Can power off same circut as P.C. |

Weight |

| 700 Pounds, Packaged Ships in a single crate. |

Dimensions |

| 133" wide by 82" deep by 97" high Table surface is 33" high |

Cutting Capacity |

|

Material Thickness.................1-1/4"inch max Material Weight..........................2000lbs max Cutting area is.................60-1/2" by 120-1/2" |

Speeds (inches per minute) |

| Cutting/rapid (X/Y)..............0.1 to 1,000 ipm Raise/lower (Z)...........................4 to 104 ipm |

Resolution |

| X/Y axes.....................................0.0005 inch Z axis............................................0.002 inch |

The DesignEdge™ software lets you work directly with the images you want to cut, eliminating any need for machine programs, layout drawings, or metal patterns. The software automatically prepares complex drawings for cutting. You simply place parts on the screen where you want them cut from the metal. You can read and convert scanned pictures and hand-drawn artwork, CAD files, and many other formats. You can add custom lettering to your designs using TrueType fonts. You can draw precise geometric shapes and modify designs with ease.

Complete Samson® System

The complete Samson® cutting system includes the machine (table with cutting grate, motors, and electronics) plus the DesignEdge™ software. You supply the plasma cutter (call for pricing), personal computer, and smoke/dust control.